Search Results

- IDNO:

- 002011

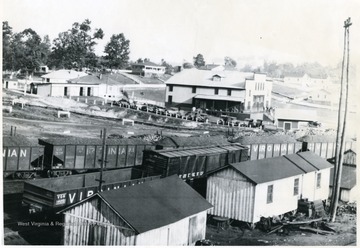

- Title:

- Virginian Train Cars Loaded with Coal; Coal Company Store in Background

- Description:

- Trains next to some houses and a store with cars parked in front of it.

- IDNO:

- 002043

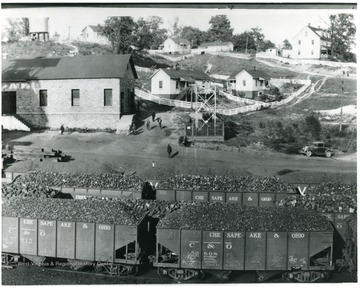

- Title:

- Chesapeake and Ohio Coal Cars in Front of Houses

- Description:

- Chesapeake and Ohio Coal train cars in front of a community of houses.

- IDNO:

- 002045

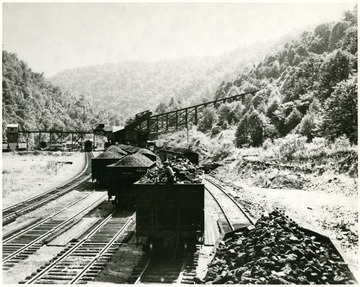

- Title:

- Loaded Coal Cars

- Description:

- Man riding in a coal car with loading facility in background.

- IDNO:

- 002046

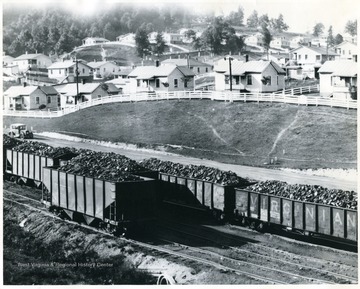

- Title:

- Virginian and Chesapeake and Ohio Coal Cars Passing By Miner's Houses

- Description:

- Virginian and C&O coal trains outside of a coal town.

- IDNO:

- 002096

- Title:

- Headquarters of the White Oak Coal Co., Macdonald, Fayette County, W. Va.

- Description:

- The maintaining of the General Offices near the mines affords opportunity for closer supervision and better co-operation between all departments. The machine and repair shops and warehouse for merchandise and mine supplies is located immediately adjacent to the office. A private branch telephone exchange with private leased lines reach each mine, giving 24 hour service. A printer telegraph instrument furnishes prompt telegraph service. Mail is received and forwarded at either Macdonald or Mount Hope post offices.

- IDNO:

- 002959

- Title:

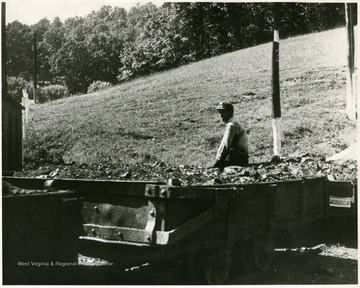

- Miner Riding on Filled Coal Car

- IDNO:

- 002963

- Title:

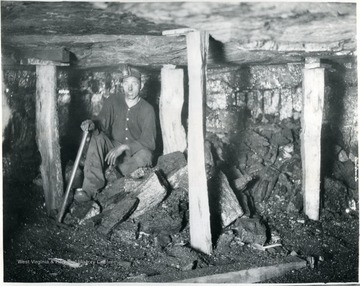

- Miner Waiting for Mine Car

- Description:

- 'Safety first is stressed in every possible way in White Oak mines. Note the posts set to protect this man at his labor. He is waiting for another mine car so he can clean up his work place and make it ready for the mining machine crew who will cut it during the night ready for him to work tomorrow.'

- IDNO:

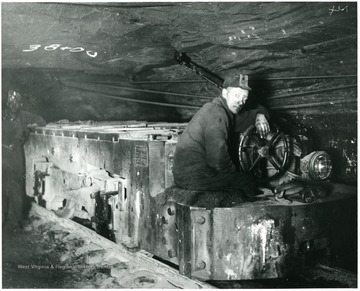

- 002986

- Title:

- Miner on Electric Locomotive

- Description:

- Two miners next to an electric locomotive.

- IDNO:

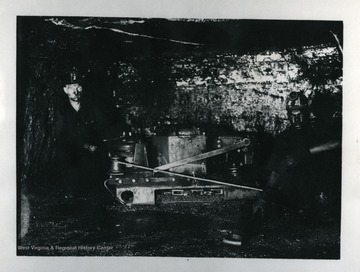

- 003049

- Title:

- Miner Operating a Cutting Machine

- Description:

- 'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and placed in cutting position as you see in this picture. The machine consists of an endless chain with bits inserted, which act as cutters. The machine cuts a kerf or hole along the bottom of the coal about 4 feet and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as bug dust. Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

- IDNO:

- 003053

- Title:

- Sewall Coal Seam Worked by the New River Coal Company

- Description:

- 'All White Oak mines work the same seam of coal, viz: Sewall...The face of one of the working places or rooms is shown in this picture. The coal averages about 48 to 50 inches in thickness. This working place is now ready to be cut by the undercutting machine, so it can be shot down by the miner and loaded into the cars for transportations to the tipple. The white line on the roof in this picture is the center line of the room set by the engineers to guide the men operating the mining machine in driving the room straight.'

- IDNO:

- 003200

- Title:

- Loading Perfectly Sized White Egg Coal

- Date:

- undated

- Description:

- 'It is any wonder White Oak is said to be the best prepared domestic coal marketed from W. VA., when you look at this picture of White egg coal taken as it is being loaded inot a a railroad car? Perfectly sized; perfectly screened and quality unsurpassed. No wonder it is the most popular sized coal sold in the domestic market.'

- IDNO:

- 003201

- Title:

- Shaker Screens

- Description:

- 'The size and design of the shaker screens now in use at the White Oak mines are the best that an experience of twenty years in preparing Smokeless Coal has found to be the best and yield a satisfactory screened and sized coal. A screen must first be of ample size to take care of the amount of tonnage passing over it, because of crowding and overloading a screen results in poorly screened and poorly sized coal. The screen shown in this picture is handling 400 tons per hour and still has ample screening space to spare. The flow of coal over these White Oak shaker screens is controlled by a feeder which cannot be become stopped up by coal sticking in the slots because the slots are wider at the base than at the top and are therefore self clearing. The lips keep the coal turning over and over so it is impossible for slack to ride over on the larger pieces. The coal never falls; it is always sliding while being screened which helps prevent breakage. Note the uniform size and firm character of the lump coal which has passed over the egg screen shown in this picture.'